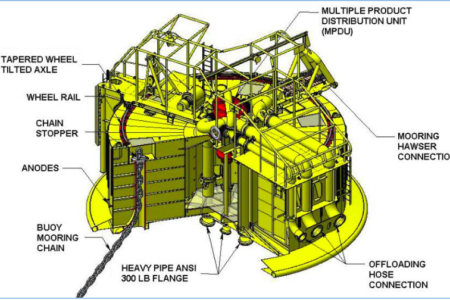

Buisier Engineering has the knowledge, experience and resources to support all of your project needs. Our dedicated staff possesses the industry experience required to meet your unique project needs on time and on budget. Please find a short list of projects completed for clients below.